When it comes to securing doors, Euro Profile Mortise Locks are a popular choice, offering reliability, ease of use, cost-efficiency, and compliance with international standards. The EN12209 standard outlines key testing and performance requirements for these locks, ensuring that they meet both safety and functionality benchmarks for various applications. This blog will explore the product inspection criteria and key features of Euro Profile Mortise Locks, detailing their compliance with the EN12209 standard.

1. Application and Performance Requirements

- Application: Euro Profile Mortise Locks are specifically designed for hinged doors, making them versatile for both residential and commercial installations.

- Mechanical Durability: These locks are tested for 200,000 cycles of use, ensuring durability even under frequent operation. The test simulates the locking and unlocking of the door, with the latch experiencing a force of 120N.

- Door Weight and Closing Force: They can accommodate door weights of up to 200kg, with a closing force requirement not exceeding 15N.

- Salt Spray Test: To resist corrosion, the lock undergoes a neutral salt spray test for 96 hours.

- Fire Resistance: The locks are certified to meet the EN1634 fire resistance standard, making them suitable for fire-rated doors.

2. Surface and Structural Integrity

- Surface Inspection: The lock’s surface must be free from burrs, scratches, stains, rust, or any other defects that could affect its aesthetic and functional performance.

- Flatness of Panels and Housing: The lock’s panel and housing should have a smooth surface with no unevenness, ensuring a seamless appearance and optimal performance.

- Lock forend and Housing Alignment: The forend should be straight without any warping, and the housing should be aligned properly to avoid misalignment or loose installation.

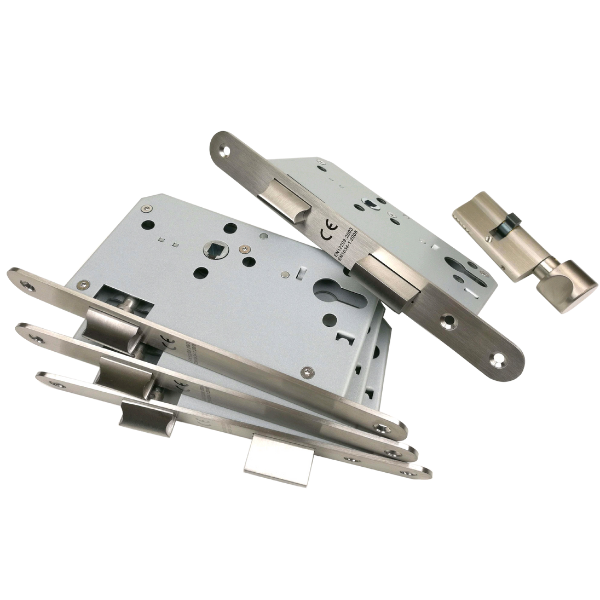

3. Locking Mechanism and Functionality

- Screws and Fasteners: The screws used in the lock must fit perfectly into their respective holes without protruding. This ensures a secure assembly that does not compromise the lock’s performance.

- Lock Body and Strike Plate Compatibility: The lock body should fit seamlessly with the strike plate, and the product comes with an ABS dust box.

- Latch Functionality: The handle should operate the latch smoothly, with the ability to reverse the direction of the latch when required. Any slight deviation in the latch’s operation (such as sticking or binding) is unacceptable.

- Euro Profile Cylinder: The Euro Profile lock cylinder should engage smoothly, with the latch retracting freely when the key is turned. This mechanism should not result in false or incomplete engagements.

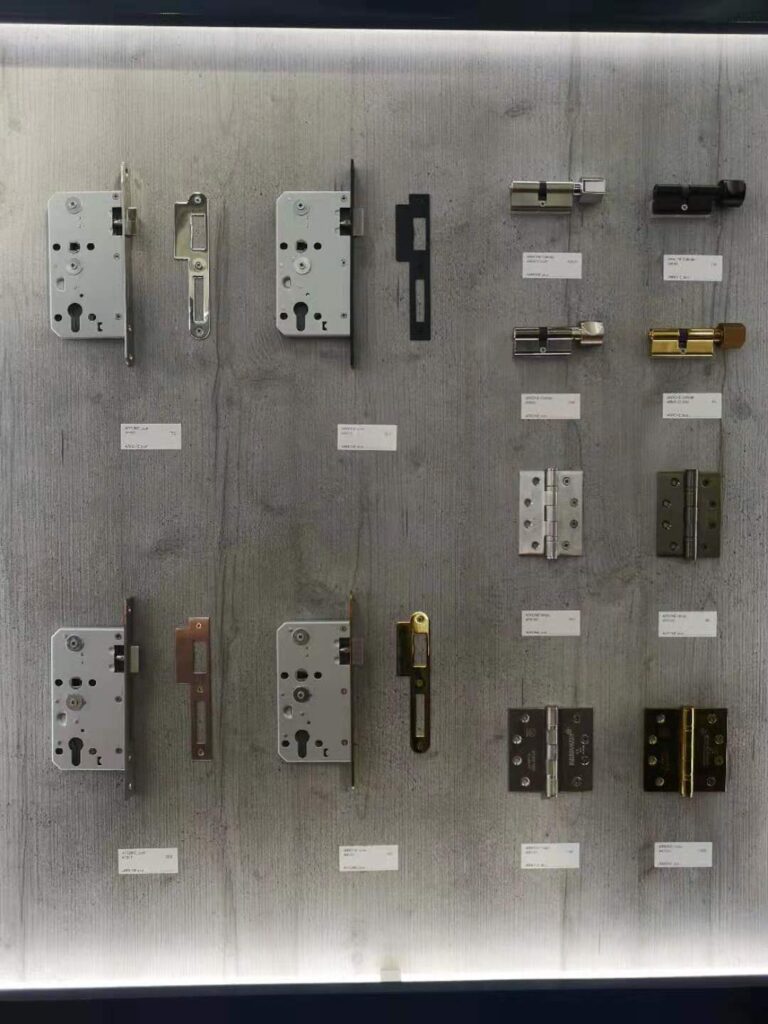

4. Detailed Functionality of Different Lock Types

- Standard Lock: Features a bolt and latch mechanism. It can be operated via the handle or lock cylinder, with the deadbolt offering two stages of extension.

- Passage Lock: This version is ideal for interior doors, with a handle-operated latch. There is no security feature, as it is used to achieve noise reduction and insulation.

- Night Lock: Typically used for exterior doors, this lock automatically locks when the door closes, requiring a key to open from the outside. The inside handle allows easy retraction of the latch.

- Bathroom Lock: Features a latch and a bolt mechanism with an emergency release function. The handle operates the latch, while the thumb-turn knob controls the bolt.

- Anti-Panic Lock: A mechanism designed for emergency exits, it allows the latch and bolt to retract in a single action from the inside room, making it ideal for safety applications.

5. Materials and Surface Treatment

- Forend: Stainless steel SUS 304 with a minimum of 8% nickel content and a brushed finish.

- Strike Plate: Made of SS 304 with the same nickel content and brushed surface treatment.

- Latches and Bolts: Constructed from SUS 304 stainless steel with a brushed finish for durability and corrosion resistance.

- Housing: Features a fingerprint-resistant galvanized steel surface to maintain aesthetic appeal even with frequent use.

- Strike Box: ABS material

6. Customization and Additional Features

Euro Profile Mortise Locks can be customized to meet the specific needs of any project. Various finishes such as satin stainless steel, gold PVD, or matte black are available, along with customized dimensions. The locks are compatible with both wood and metal doors, and can be equipped with both wood-threaded and machine-threaded screws as per customer requirements.

7. Durability and Long-Term Performance

To ensure the longevity of Euro Profile Mortise Locks, regular maintenance and lubrication are essential. Applying a lubricant to the internal mechanisms can prevent wear and ensure smooth operation throughout the lock’s lifespan. Regularly checking for signs of rust, dirt buildup, or misalignment can further prolong the life of the lock.

Conclusion

Euro Profile Mortise Locks, compliant with EN12209 and other relevant standards, offer a secure and durable solution for various door applications. Their functionality, ease of use, and adaptability make them an essential component in modern security systems. By adhering to rigorous testing and quality control processes, these locks guarantee both safety and convenience for users, making them a trusted choice for residential, commercial, and industrial applications.

If you need any help about euro profile mortise fire-rated locks, please don’t hesitate to contact SDH hardware: info@sdhhardware.com