— How SDH Ensures a Premium Matte Black Finish

At SDH, we believe that quality is not just seen — it’s felt. Our concealed hinges are engineered with precision and refined through advanced surface treatments. One of the most important steps in that process is vibratory polishing, especially when producing popular finishes like matte black.

In this blog, we’ll explore what polishing means in metalworking, compare common techniques, and show why vibratory polishing is the ideal choice for concealed hinges.

🧽 What Is Polishing?

Polishing is the process of refining a metal surface by removing imperfections such as burrs, tool marks, and sharp edges. For concealed hinges, polishing plays a vital role in:

- Enhancing aesthetics

- Improving surface smoothness

- Preparing for coatings and plating

- Increasing corrosion resistance

🔍 Types of Polishing in Hardware Manufacturing

- Manual Polishing

- Performed by hand using abrasives or polishing wheels.

- Suitable for complex geometries but labor-intensive and inconsistent.

- Vibratory Polishing (Vibratory Finishing)

- A batch process where parts and abrasive media vibrate together in a tub.

- Highly efficient and consistent across large volumes.

- Buffing / Mirror Polishing

- Used for glossy, decorative finishes.

- Not typically needed for concealed parts.(SDH provide polished finish, like Gold PVD, polished chrome)

- Electropolishing

- Electrochemical technique mostly used for medical or food-grade components.

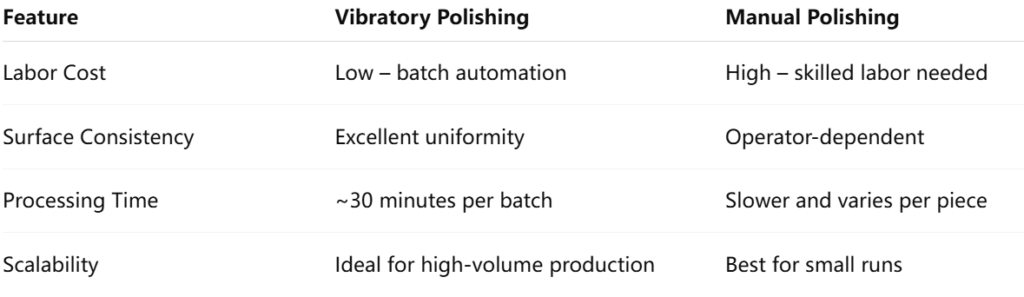

⚙️ Vibratory Polishing vs. Manual Polishing

At SDH, each batch of hinges undergoes a 30-minute vibratory polishing cycle, using carefully selected abrasive media matched to the hinge material. This ensures optimal results in both function and appearance.

🎯 Why Vibratory Polishing Is Ideal for Matte Black Hinges

Matte black is one of the most sought-after finishes in modern interior design. But achieving a smooth, even matte look requires a flawless base surface — because matte coatings tend to reveal even the smallest surface defects.

That’s where vibratory polishing makes the difference:

- Produces a satin-smooth surface ideal for matte coating

- Eliminates burrs and imperfections that can cause coating failure

- Delivers a consistent texture across all hinge surfaces

- Reduces manual handling, ensuring clean, uniform parts

🏆 SDH Commitment to Quality

At SDH, we don’t cut corners. Every hinge goes through our carefully developed vibratory finishing system, followed by inspection before coating and assembly. Whether your customers are looking for durability, minimalism, or visual consistency, our hinges deliver performance that lasts.

Vibratory polishing may be invisible in the final product — but its effects are impossible to ignore.

📞 Looking for premium concealed hinges?

Contact SDH today to request samples or learn more about our production process.

We’re here to help you build better, smoother, and more beautiful hardware.