When it comes to door hardware, corrosion resistance is not just about appearance — it’s a matter of durability, safety, and long-term value. Whether you’re working on a coastal hotel project or outfitting interior residential doors, understanding how well your hardware can withstand harsh conditions is crucial. One of the most widely recognized methods to assess this is the salt spray test.

In this article, we’ll take a deep dive into what the salt spray test is, why it’s essential for door hardware, how to interpret test results, and how manufacturers like SDH ensure reliable performance with salt spray testing.

What is the Salt Spray Test?

The salt spray test, also known as the salt fog test, is an accelerated corrosion test designed to simulate harsh environmental conditions — particularly those involving exposure to salt-laden air or moisture. It’s commonly used in the hardware, automotive, and construction industries to assess how resistant a product’s surface finish is to rust and corrosion.

This test is typically conducted in a sealed chamber where a fine mist of 5% sodium chloride (NaCl) solution is continuously sprayed at a controlled temperature, usually around 35°C (95°F). The exposure duration can range from 24 hours to over 1000 hours, depending on the product’s intended environment and the level of protection required.

Several standards regulate the procedure of salt spray testing, such as:

- ASTM B117 (commonly used in North America)

- ISO 9227 (international standard)

The outcome of the test is visually evaluated for signs of rust, blistering, pitting, or discoloration. This provides a consistent benchmark for comparing products and surface treatments.

Why Is Salt Spray Testing Important in Door Hardware?

Door hardware — including handles, locks, hinges, and latches — is constantly exposed to the elements. In humid or coastal environments, salt and moisture can quickly lead to corrosion if the hardware is not adequately protected.

Salt spray testing is essential for several reasons:

- Predicts Performance: It simulates years of environmental exposure within a much shorter timeframe.

- Validates Surface Treatments: Verifies the effectiveness of electroplating, powder coating, PVD, and other finishes.

- Ensures Compliance: Many building codes or project specifications require corrosion-resistant hardware tested to a specific standard.

- Reduces Failures: Helps prevent premature rusting, mechanical failure, and costly replacements.

In short, the salt spray test is a reliable way for architects, contractors, and buyers to assess whether the hardware they choose will perform well in its intended setting.

Understanding Test Results: What Do the Hours Really Mean?

Salt spray test results are typically expressed in hours — the number of hours the sample can withstand salt exposure without visible corrosion. While this is not a direct correlation to real-world lifespan, it provides a comparative measure across materials and finishes.

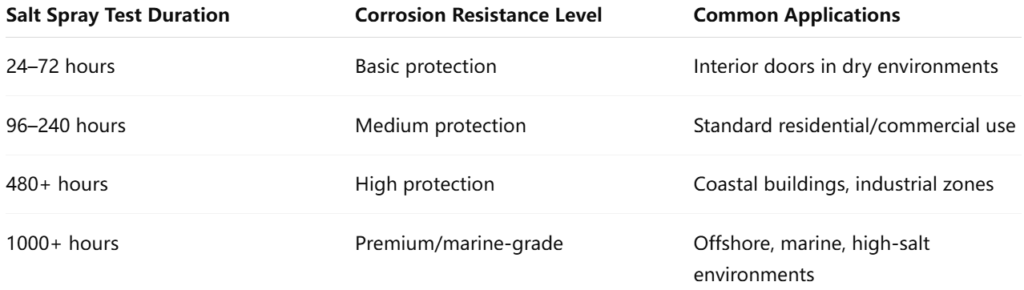

Here’s a general breakdown of salt spray test durations and their corresponding protection levels:

For example, a zinc-plated steel hinge that passes 96 hours of salt spray testing shows decent resistance for most indoor or general commercial uses. In contrast, 304 or 316 stainless steel may pass 480 to 1000 hours, suitable for aggressive environments.

It’s important to note that salt spray testing does not reflect actual in-field lifespan, but is useful for benchmarking relative performance.

How SDH Ensures Reliable Corrosion Resistance

At SDH, we take corrosion resistance seriously. Our door hardware undergoes strict quality control procedures — including salt spray testing — to ensure durability and reliability.

Our surface finishes are engineered for performance:

Electroplated coatings on our standard products consistently pass 96 hours of salt spray testing, offering robust protection for most residential and commercial applications.

SDH hardware ensures long-lasting protection even in challenging environments by optimizing plating thickness, selecting corrosion-resistant substrates, and maintaining rigorous process control.

Choosing Door Hardware Based on Salt Spray Performance

So, how do you choose the right level of corrosion resistance for your project?

Here are some quick recommendations:

- Indoor use (dry areas): 24–96 hours is typically sufficient.

- Public/commercial buildings: Aim for 96–240 hours.

- Bathrooms, kitchens, and humid areas: Minimum 240 hours recommended.

- Coastal or industrial settings: 480+ hours or stainless steel hardware.

When evaluating hardware suppliers, always ask for salt spray test reports or product certification based on relevant standards (e.g., EN 1670). Don’t be misled by vague marketing terms like “rustproof” without supporting data.

Conclusion

Salt spray testing is one of the most practical and effective tools for evaluating the corrosion resistance of door hardware. It provides valuable insight into how materials and finishes will hold up over time and helps buyers make informed, reliable decisions.

At SDH, we’re proud to deliver products that combine design, functionality, and verified durability — so your projects not only look good but last longer.

Want to learn more about our salt spray-tested products or request a technical datasheet? Contact us today.