The cylinder is the main part of the door lock, it’s also the heart of the lock, when turning the cylinder knob or key, the cylinder cam can drive the lock bolt movement.

Lock cylinder adopts a number of anti-theft technology, a variety of shaped anti-pulling ejectors, to eliminate technical opening, with a unique design of the ejector and blade structure, it has a high anti-technical opening security performance. The lock is equipped with precision numbered marbles and shaped marbles structure, the numbered marbles, and shaped marbles must be pulled at the same time when the technical opening will automatically lock the case so that the technical opening is without success. The lock cylinder adopts multiple combinations of shaped marbles, which can compile up to billions of key numbers, thus achieving zero mutual opening of the area (one in sixteen million). The lock cylinder adds a lateral inward pressure type side column card pin device, which greatly improves the ability to prevent violent strong twisting.

(A) bullet type lock cylinder

- The classification of the bullet-type lock cylinder

(1) By key.

British / ordinary lock cylinder (British / ordinary key)

More product info

Plane / computer lock cylinder (plane / computer key)

View more info

Cross cylinder (cross key)

(2) According to the shape: European-style lock cylinder, oval, round

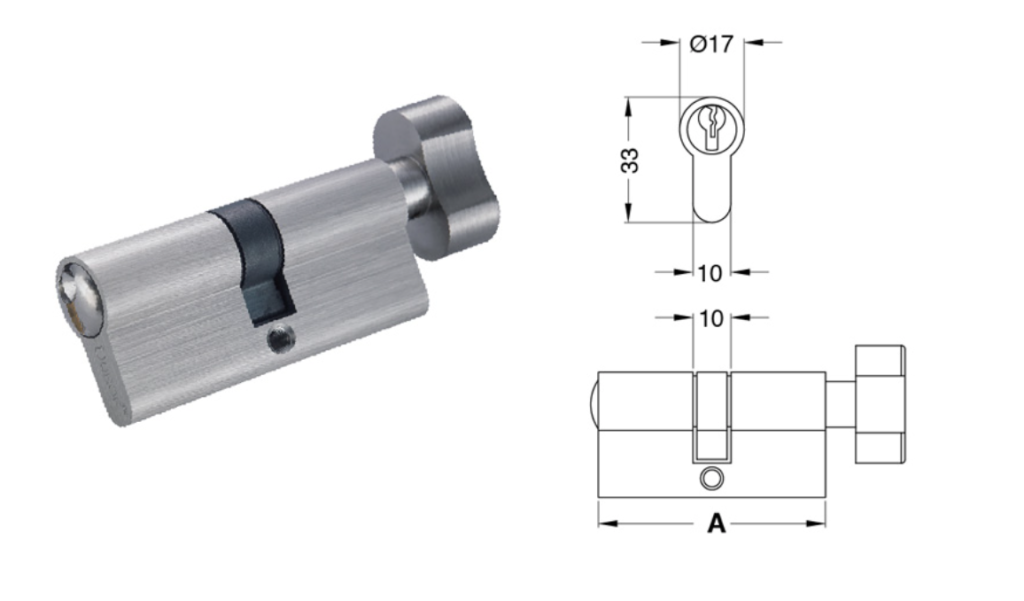

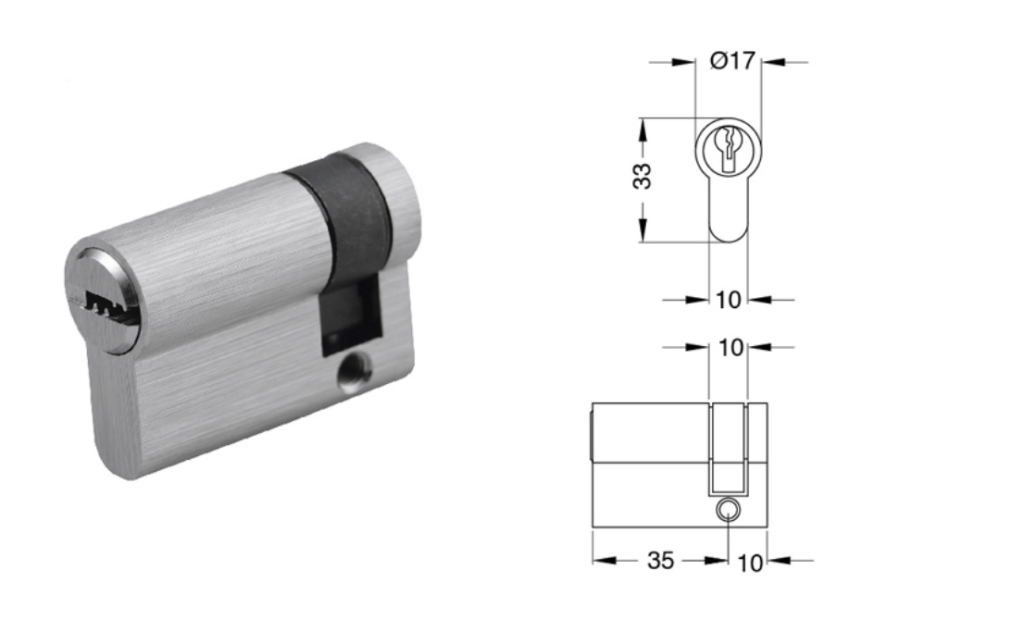

(3) by function: double sie opening lock cylinder, single-opening lock cylinder with turn knob, half cylinder, bathroom cylinder, etc.

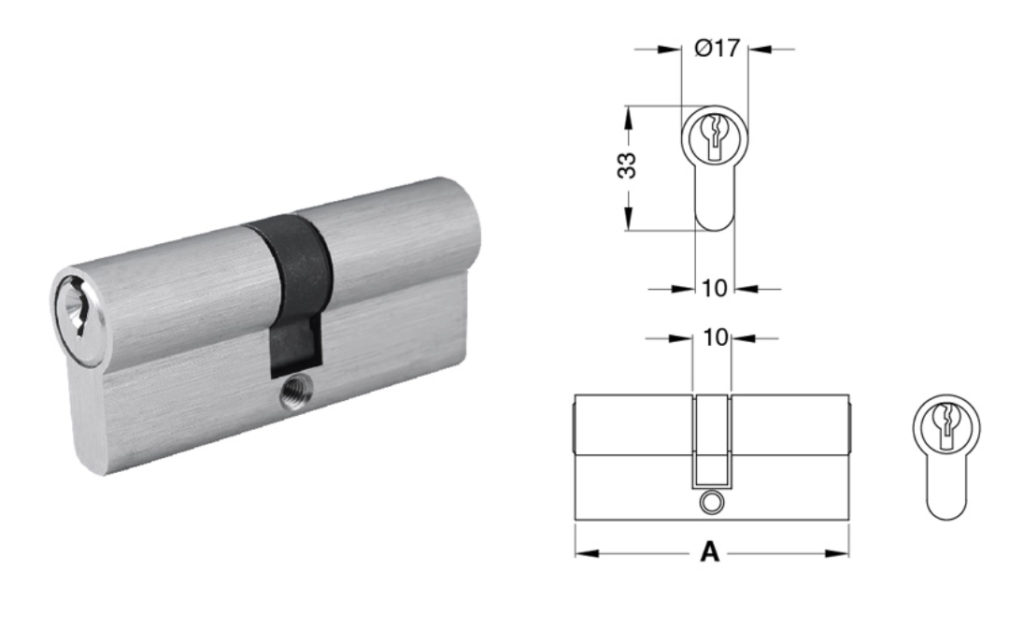

- European style lock cylinder size.

End face outline size: 33X17X10

Length C=A+B

The standard width of the wheel slot is 10MM

- Door lock cylinder assembly

Cylinder + key + mounting screws

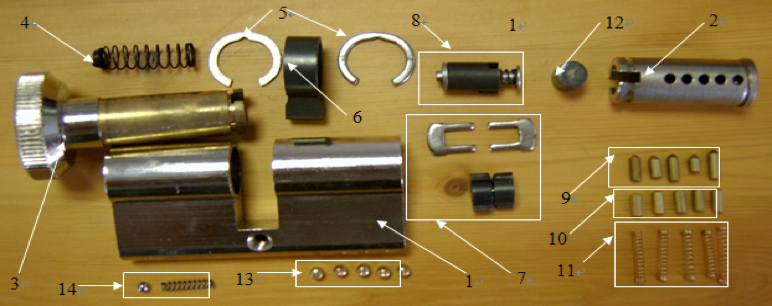

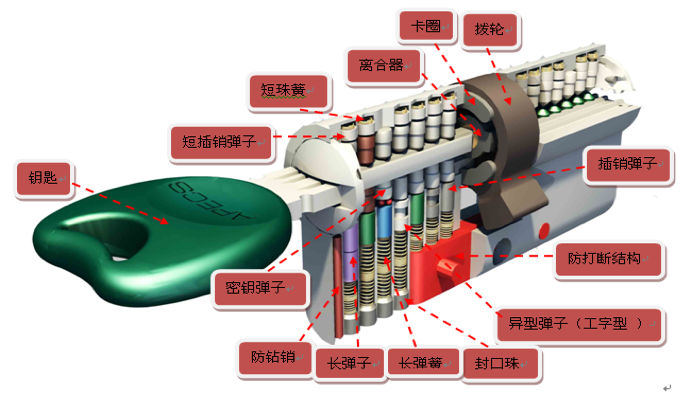

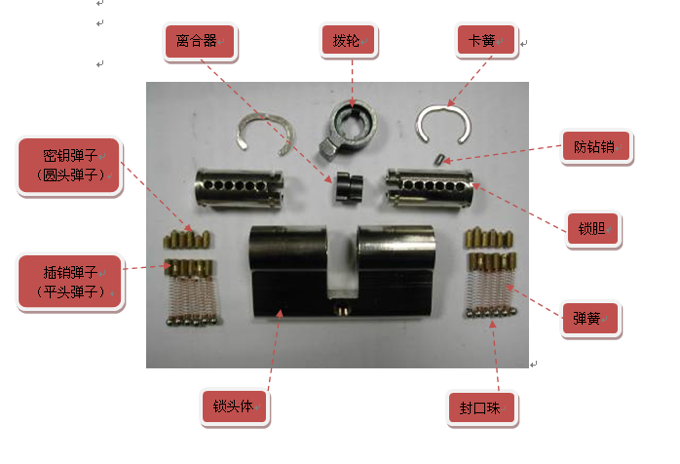

- Euro lock cylinder parts

- The structure of the bullet type lock cylinder

(1) lock core body/lock head body: the outermost layer of the entire lock cylinder, playing a role in protecting all the internal parts, its shape should also be suitable for the overall installation of the door lock.

(2) lock cylinder: the key is inserted and the part that turns with the key. Lock guts inside the main key bullet, in the original state without the insertion of the key, the length of the part of the pin bullet is also inside it.

(3) Marbles.

1) Key marbles (lower marbles / round-headed marbles): the key marbles are located in the lock liner, after inserting the key, underneath it, in contact with the key, and with the shape and position of its tooth flower.

2) The length of the key bullet depends on the diameter of the lock cylinder, the length is set according to the common lock cylinder diameter Φ13, its shortest is 4.2 and the longest is 6.7.

3) Level difference of the key bullet: the number of differences in the length of two adjacent different bullets. Generally there are three standard gradations – 40 filaments, 50 filaments, 60 filaments, (1 filament = 0.01 mm). The greater the difference, the better the secrecy, and anti-dial ability, 0.60 grade difference is the most ideal, but considering the lock structure generally choose a 0.5-grade difference.

4) Pin bullet (flush bullet/upper bullet): When the lock is mounted upside down, the pin bullet is located below the key bullet, the upper part of the spring, and its length is generally the same. When the lock is mounted positively, the latch popper is not in direct contact with the key, one end is in contact with the round popper and one end is in contact with the spring.

5) anti-dial bullet (shaped bullet): is a kind of latch bullet, that play the role of anti-dial.

(4) spring: the spring is located in the lower part of the lock core body, and the upper end of the spring is in contact with the latch spring. Usually, one end of the spring is in contact with the latch spring, and one end is in contact with the sealing bead, mainly by its expansion and contraction of the elasticity of the action of the latch spring.

1) clutch: direct action on the paddle wheel, so that the paddle wheel rotation.

(6) Paddle wheel (fork).

Independently located in the milled part of the lock body, the part that can be rotated. It is placed in the 10 mm slot milled in the lock body (opposite in the middle, eccentric on both sides), with a thickness of about 7.8 mm, and is sandwiched between two circlips and can be rotated. Lock core mainly through the dial to interact with the lock body, for the insert door lock, when the dial wheel pushes the lock body in the gear plate, you can open or lock the main tongue, when the dial wheel pushes the oblique tongue linkage, you can reach the key to open the oblique tongue. Usually, there are U-shaped clutch wheels, round clutch wheels, knob clutch wheels.

(7) Snap ring (snap spring/clip).

Ring-shaped metal sheets, usually iron, there are also steel or copper sheet, mainly to play a role in fixing the role of the connection between the dial wheel and the lock cylinder. There are different thicknesses, usually using 1.0mm thickness, too thick will cause the lock cylinder can not turn or smooth, too thin will lead to the dial wheel and lock core shaking more powerful. According to the size of the dense fit, can also be divided into a 270-degree snap ring and a 360-degree snap ring. For an ordinary lock cylinder, just destroy the snap ring, you can take out the dial wheel, take out the lock cylinder.

(8) sealing bead: sealing the bead of the bullet hole to keep the internal parts (bullet spring) from falling out.

(9) Inner twist: Use the key outside the door and the knob inside the door.

(10) Key: for the lock cylinder accessories, used to open the door lock.

Thickness: 2.0mm for ordinary keys (English keys); 2.4-3.0mm for flat slug keys.

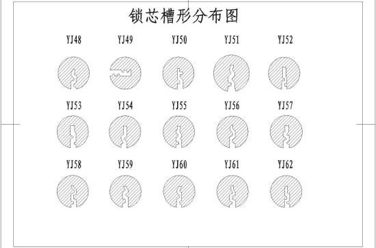

Key slot shape: the shape of the key cross-section, that is, the shape of the keyhole. Commonly used keys are divided into straight slot type and S slot type as shown in the figure.

The straight slot type is easy to process, but the anti-dial performance is poor; the S slot in the S closed center line, anti-dial performance is good, but manufacturing difficulties.

Tooth pattern: teeth or holes of different depths milled (for English keys) or drilled (for flat keys) in the key. Each tooth/hole corresponds to a key bullet. Deep teeth/holes correspond to long slugs, shallow teeth/holes correspond to short slugs.

More slot types are shown in the following figure.

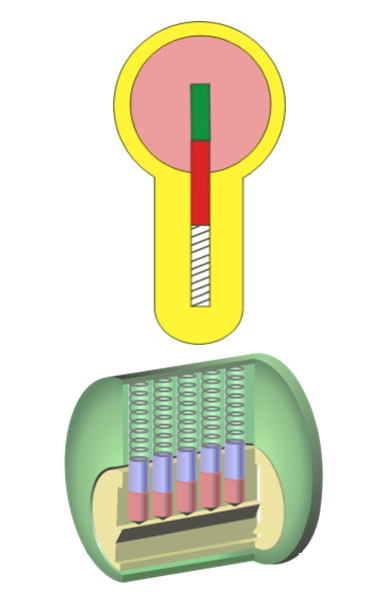

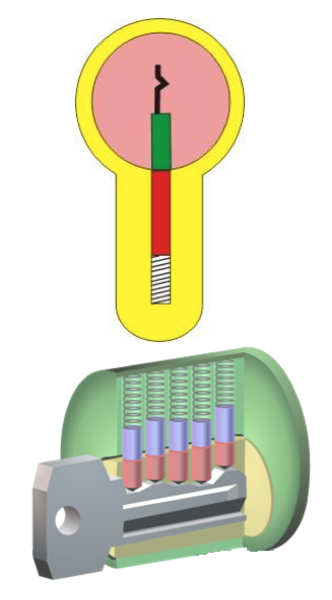

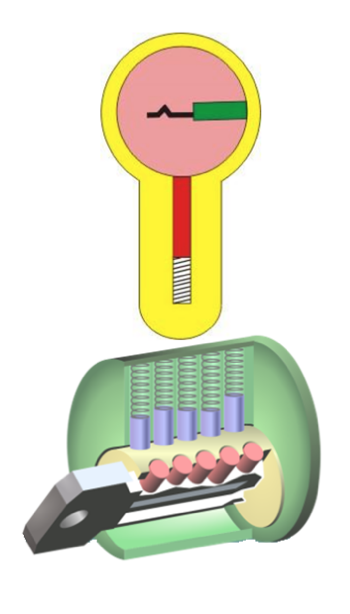

- Working principle of bullet type lock cylinder

Classification: English key, flat key, cross key

Description of the principle: Inside the lock cylinder, the bullet hole inside the cylinder corresponds to the bullet hole inside the lock cylinder. When the key is not inserted, all the pins are partially inserted into the lock cylinder under the action of the spring, which connects the lock cylinder to the lock body, making the lock cylinder unable to turn and the lock unable to open. When the correct key is inserted, the key teeth just coincide with each key bullet, the key presses down on the key bullet and pins all the pins in the lock cylinder are inserted into the lock core body flush with the lock cylinder cut surface, the lock cylinder is detached from the lock body, the key can drive the lock cylinder to rotate freely and at the same time drive the paddle wheel to rotate and play the role of opening the lock.

The result of using the incorrect key to open the lock.

1) the tooth flower of the wrong key does not match the key bullet, the latch bullet is not all topped back into the lock core body or the key bullet is topped out of the lock cylinder into the lock core body so that the lock cylinder cannot turn and cannot be opened.

2) The wrong key and the correct key cross-section is different, the lock cylinder slot type is different and simply can not be inserted into the lock cylinder.

- Key volume and interlocking rate of the cylinder

(1) Key quantity (number of teeth/key combination)

Calculation of the theoretical key quantity: the number of key poppets of the key poppet type is subdivided by the number of key poppets.

Theoretical key volume = the number of different lengths of the type of bullet number of bullets

If in a lock cylinder, using 2 different lengths of key poppets, there are three key poppets, the theoretical key quantity generated is 23 = 8. The number of key poppets of different lengths is the base number, and the poppet hole of the lock cylinder is the exponent. If there are 6 different lengths of keyed marbles to choose from, installed in the lock cylinder with 5 holes in the empty, the amount of theoretical keys generated will be 65 = 7776, but there are many numbers that can not be used, such as 11111 and other 5 numbers consisting of the same marbles, equivalent to the flat key must be removed. According to the requirements of the same key must have 3 or more different dental flowers to use. Such as 12344 so as to reduce the mutual opening. So when we choose a lock, try to pick a key with a large variety of tooth blossoms.

The difference between the theoretical key volume and the actual key volume.

The theoretical key amount is quite large, but in the actual production process calculated the final key amount is often very different from the theoretical key amount, the key amount is subject to many factors, such as: can not be used in a lock core is all the same length of the key bullet; the same length of the key bullet can not appear several times at the same time, etc., because the lock core with these characteristics can easily be used technical methods, blank vibration, etc. The way to open, poor security performance.

Key table:

The production list of each batch of lock cylinders according to the method of permutation, in order to facilitate production. In case of CNC processing, the data of this table is automatically generated by the computer for production; in case of manual operation, this table should be referred to for production.

Manual coding is as follows (6 bullets, 5 holes, every 6 into 1 all the way to 66666)

(2) Mutual opening rate

Mutual open rate: is the ratio of the number of mutually open lock cores to the number of sampled lock cores. The smaller the ratio, the better. Factories usually make a production list (key table) based on the method of permutation for mass production. Usually, 5 levels of difference, 6 bullets, 5 bullet holes, the number that can be used are about 6000, after 6000 products will start a new cycle, so as far as possible, the batch of lock cylinders produced according to the same list is sent to distributors with a long interval, in order to achieve the purpose of avoiding the same pattern open each other. The factory will also often change the groove shape of each batch of cylinders produced according to the same list, so as to further avoid mutual opening and repeat production of the same cylinders.

Reducing interlocking: Interlocking should be controlled within the standard range, i.e. a cylinder can only be opened by the key that the cylinder is equipped with. Manufacturing different slot shapes (straight slot type and S type) and improving the processing accuracy of the lock cylinder, guts and keys can avoid mutual opening to a certain extent.

Inspection method of mutual opening rate: In order to avoid mutual opening conditions, the factory usually adopts a series of testing methods of sampling-coding-pair testing. The process is to randomly select a number of lock cores in the same batch of lock cores, code each group of corresponding keys and lock cores (such as No. 1 key corresponding to No. 1 lock core), and then use each coded key to try to open the other coded lock cores, while recording the number of openable lock cores.

- manufacturing process and manufacturing difficulties of the lock cylinder

Manufacturing process. - core body: break material – drilling large holes, reaming, reaming – drilling the lock gall connection slot – drilling the ball hole – drilling the core mounting holes and tapping. -Drilling the core mounting holes and tapping the internal threads -Milling the paddle wheel slot -Stamping (marking)

2、Lock core: break material (sometimes no separate break material) – fine turning of the outer circle – turning of the snap ring slot – drilling (milling) key guide slot – – slotting (slotting machine) -Pull slot (pull slot machine)

3, key: stamping key shape – milling groove – drilling (milling) tooth flower

Manufacturing difficulties:

The machining accuracy of parts and fit clearance

The processing accuracy of the bullet: the accuracy of the high-quality bullet can reach plus or minus 0.02mm, the accuracy of the general factory production of the bullet is 0.05mm.

The processing accuracy of the key tooth flower: the key with the keyhole clearance: 0.15mm.

The clearance between the lock core body and the lock cylinder: 0.08-0.15mm.

Mating clearance between the marble hole and the marble: 0.1-0.15mm.

10. additional functions of the lock cylinder

(1) AB key lock cylinder

Master key and decoration key, when the room is decorated, once the master key turns the lock cylinder, the decoration key will not be able to open the lock cylinder.

(2) Management key lock cylinder

Management key lock cylinder: the same key can open different lock cylinders. Such as the hotel manager key can open all floors of the lock cylinder, the floor manager can open a floor lock cylinder, guests can only open their personal door. Where the manager and floor manager use the key lock cylinder is the management key lock cylinder.

Management key cylinders are also called master key systems with up to 5 levels.