This European Standard incorporates dated or undated references, provisions from other publications. These normative references are cited at the appropriate places in the text, and the publications are listed hereafter. For dated references, subsequent amendments to or revisions of any of these publications apply to this European Standard only when incorporated in it by amendment or revision. For undated references, the latest edition of the publication referred to applies (including amendments).

EN 1634-1, Fire resistance tests for door and shutter assemblies – Part 1 : Fire doors and shutters.

EN 1670:1998, Building hardware — Corrosion resistance — Requirements and test methods.

EN 12519, Doors and windows — Terminology.

Classification

Coding system

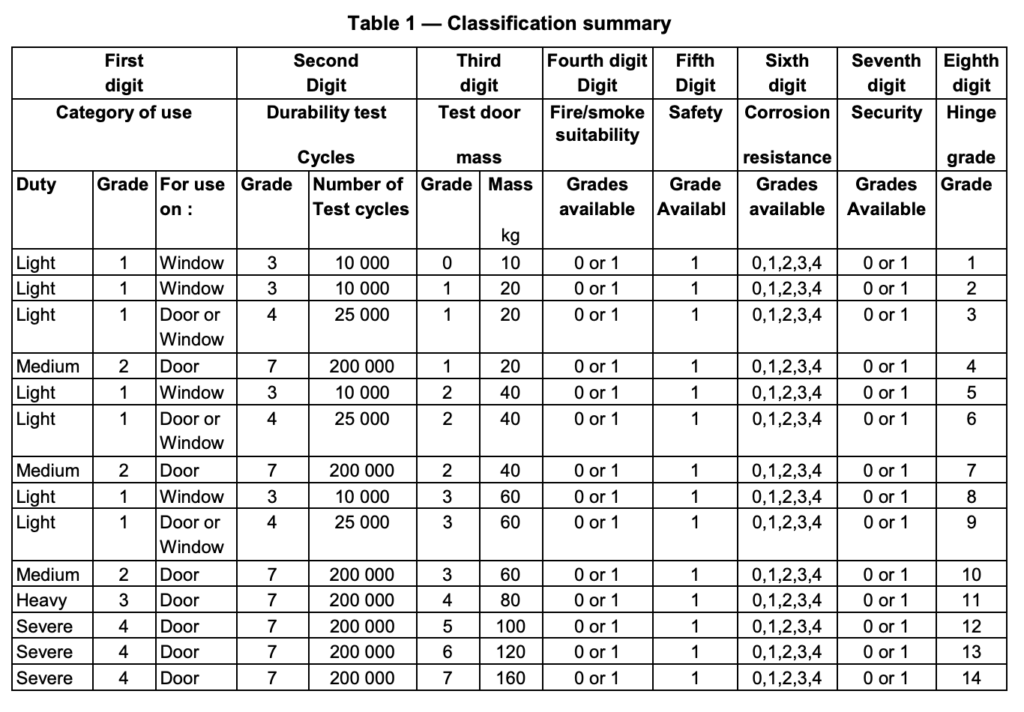

For the purposes of this European Standard, hinges shall be classified according to the eight digit coding system

described in 4.2 to 4.9.

1. Category of use (first digit)

Four categories of use are identified for hinges. Annex A defines the typical applications of hinge grades.

2. Durability (second digit)

Three grades are identified for hinges manufactured to this European Standard.

Hinges are graded according to their frequency of use and the maximum mass of the hinged element with which

they may be used, in accordance with Table 1.

Hinges intended for use only on windows are tested to:-

grade 3 : 10 000 cycles

grade 4 : 25 000 cycles

Hinges intended for use on doors are tested to:-

grade 4 : 25 000 cycles

grade 7 : 200 000 cycles

3. Test door mass (third digit)

Eight grades are identified according to Table 1 of this European Standard.

4. Suitability for use on fire/smoke compartmentation doors (fourth digit)

Two grades of suitability for use on fire/smoke compartmentation doors are identified for hinges manufactured to

this European Standard:

grade 0: not suitable for use on fire resistant and/or smoke control door assemblies;

grade 1: suitable for use on fire/smoke resistant door assemblies subject to satisfactory assessment of the

contribution of the hinges to the fire resistance of the specified fire/door assemblies. Such assessment is

beyond the scope of this European Standard (see EN 1634-1).

NOTE Annex B indicates additional requirements for hinges to grade 1.

5. Safety (fifth digit)

All hinges are required to satisfy the essential requirement of safety in use. Therefore only grade 1 is identified.

6. Corrosion resistance (sixth digit)

Five grades of corrosion resistance are identified according to EN 1670:

grade 0: no defined corrosion resistance;

grade 1: mild resistance;

grade 2: moderate resistance;

grade 3: high resistance;

grade 4: very high resistance.

7. Security – Burglar resistance (seventh digit)

Two grades of security are identified for hinges manufactured to this European Standard.

grade 0: not suitable for use on burglar-resistant door assemblies;

grade 1: suitable for use on burglar-resistant door assemblies, subject to satisfactory assessment of the

contribution of the hinges to the burglar resistance of specified burglar-resistant door assemblies. Such

8. Hinge grade (eighth digit)

Fourteen grades of the hinge are identified in this European Standard, as listed in Table 1.

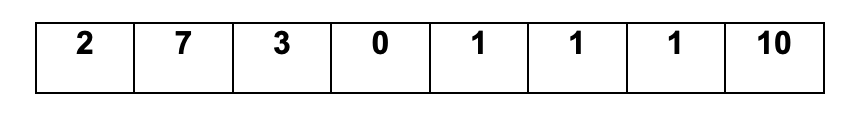

Example of classification

This denotes a hinge for use in medium-duty situations tested to 200 000 cycles, for use on doors with a mass up to 60 kg, with no stated fire resistance, mild corrosion resistance, suitable for use on burglar-resistant doors, and with a hinge grading of 10.