Door hardware is an integral part of our daily life. When we choose door hardware products such as hinges, lock bodies, lock cylinders and handles, material is an important consideration. The quality of materials is related to the actual service life of hardware products, and the choice of materials can make a big difference in terms of aesthetics, durability and sustainability.

To deepen the topic, SDH has listed below the characteristics of the four most common door hardware materials, as well as the most common materials for hinges, lock bodies, lock cylinders and handles, allowing you to decide which material is best for your project Need to make an informed decision.

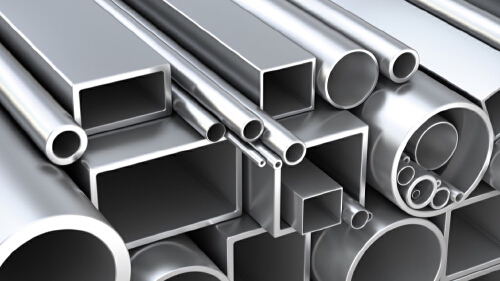

Stainless steel (304)

The tensile strength is about 550MPa, the hardness is about 150-160HB, the strength and toughness are higher than ordinary cast iron, and it can be cold-formed, but not forged. The melting point is 1534°C.

Aluminum alloy

The hardness ranges from HB60-150, the tensile strength of 6063-T5 is not less than 160MPA, and can be cast, stretched, die-casted and other processes with a melting point of 660 degrees Celsius.

Zinc alloy

Hardness HB65-140, tensile strength 260-440MPa, melting point 419.5 degrees Celsius.

Brass

Hardness HB95-114, tensile strength 350Mpa, suitable for bending and stretching processing, good ductility, melting point 930 degrees Celsius.

The lock cylinder

The lock cylinder is an important part of the lock, which determines the durability and safety of a set of locks, from the lock body to the edge of the door. We can choose different materials to make the lock cylinder, such as aluminum, zinc alloy, brass, and stainless steel.

If you choose a cheap lock cylinder, you can choose an aluminum-zinc lock cylinder, but it is easy to break, and its strength and toughness are not good.

If you choose a lock cylinder for a fire door with a long fire protection time, a stainless steel lock cylinder is the best choice, but the price is high, and the production is not easy to process.

For brass cylinders, it is the most common choice that can meet all the conditions of daily use. Brass has good hardness and toughness, not easy to break; not easy to rust, has self-lubricating properties; wear-resistant.

The mortise lock

The Mortise lock is installed on the inside of the door frame and is the part that determines the durability of a set of locks. Mortise lock is made of metal or metal alloy, common materials are stainless steel and brass and other hard materials with high durability and high precision. Commonly used materials for Mortise locks are SS316, SS304 and SS201. For stainless steel mortise locks, they are usually used for long-term fire-rated doors. SDH’s mortise locks have CE marks and fire ratings. The lock body can keep the surface smooth for a long time, not easy to rust and wear-resistant, these two characteristics greatly improve the service life of the mortise lock. Euro mortise lock can also maintain long-term lubrication, and it has been installed and used, which is convenient for you to open and close the door and can bring you a high degree of safety and aesthetics.

Specifically, Deadbolt, Latchbolt, forend and strike plate made of SUS304; Lockcase: Steel galvanized with blue coating

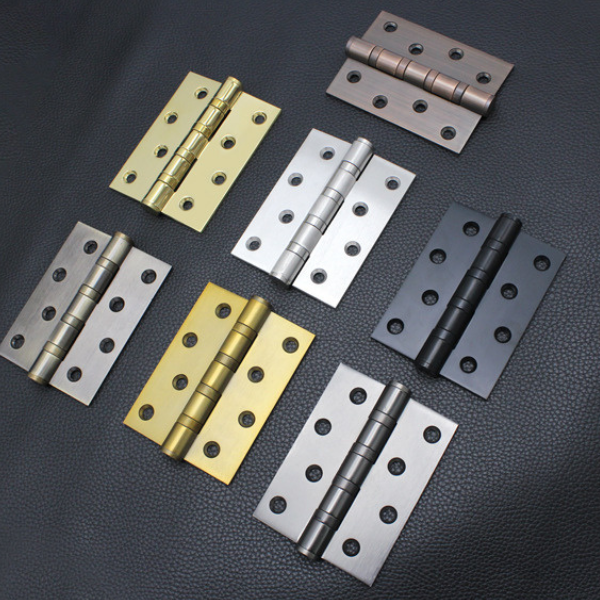

The butt hinge

The most common hinge is the butt hinge, which can be found on most doors in a home or office. Butt hinges are made from a variety of different materials, including stainless steel, brass, and more.

Due to the applications in which they are applied, the hinges need to be able to withstand the stress of constant opening and closing. In order to meet this requirement, most butt hinges are made of stainless steel, because stainless steel can resist corrosion and rust, because hinges used on the outside are exposed to the water and salt of the environment, and damage will occur quickly.

SDH uses stainless steel to make the European standard butt hinge, with a thickness of 3mm, which is hard enough to ensure the load-bearing capacity of the hinge. And passed the 96h neutral salt spray test, can be used in seaside environment, not easy to rust. In addition, stainless steel butt hinge is the best choice for fire doors. The melting point of stainless steel is about 1400°C, and the temperature of the flame is about 2100°C. SDH’s butt hinge can pass the 4h fire test.

The butt hinge made of solid brass is very strong. Brass is a tensile metal that bends and doesn’t break easily, and its flexibility and durability can make brass the perfect material for a strong hinge. Brass has excellent corrosion resistance, is less likely to rust and lasts longer, and has been used as a home building material.

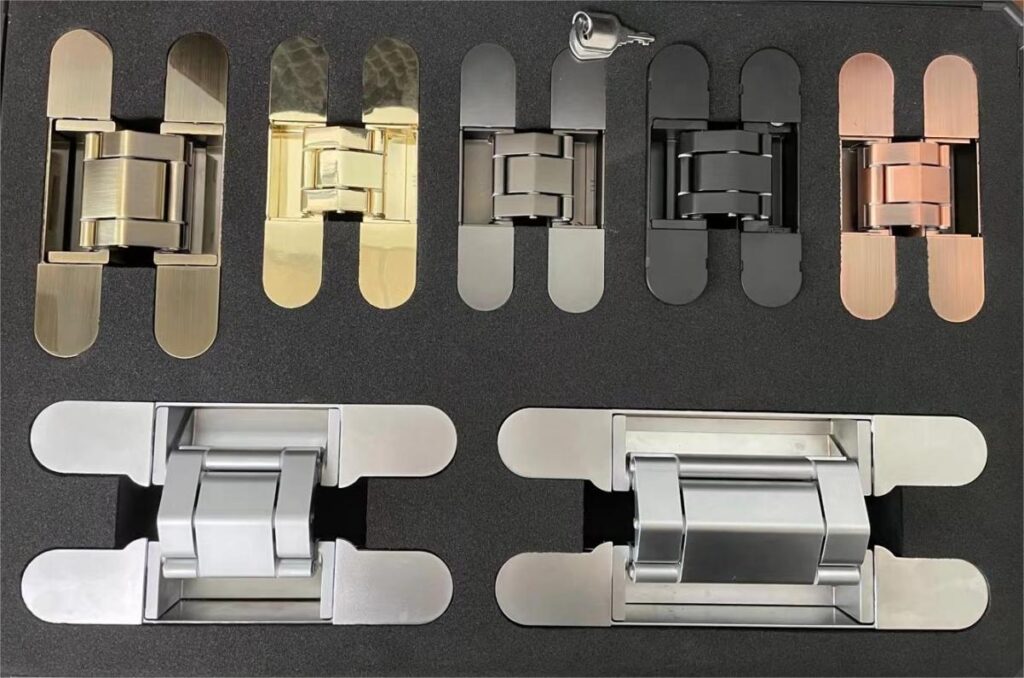

3D adjustable concealed hinge

Compared with butt hinge, 3D adjustable concealed hinge can not only adjust the position of the door after installation, which is more practical and beautiful, but also can adjust the position of the door to prevent the door from sagging.

Most of the 3D adjustable concealed hinges are made of zinc alloy and stainless steel. Zinc alloy has good ductility, no rust, wear resistance, and can keep the surface smooth for a long time. These two characteristics greatly reduce the possibility of aging and damage of 3D adjustable concealed hinge.

Stainless steel 3D concealed door hinge is used for Heavy duty doors. SDH’s SH Series Concealed hinge is made of stainless steel, anti-corrosion, good load-bearing performance.

The door handle

Door handles for interior doors, exterior doors and fire doors complying with European EN1906 standard, most door handles are made of stainless steel, brass, zinc alloy and nylon.

Stainless steel is durable and can resist corrosion and rust, its strength makes it difficult to be broken, adding more security, it is the best choice for door handles, to ensure the service life of door handles and minimize the loss of locks damage, is one of the most durable and functional handle materials.

Brass has a unique golden hue. But without special treatment, brass reacts naturally to environmental conditions, causing it to corrode to form a brown or brown-green patina. Because of its malleability, brass is ideal for customization and is a second choice for decorative applications. Brass is fire resistant and protects the door or what is behind it from fire damage. Brass door handles are beautiful and elegant.

Zinc alloy handles come in many forms and finishes, are cost-effective and affordable. Zinc door handles are durable, rust and corrosion resistant.

Nylon handles are often used in hospitals and schools, etc. The inside of the door handle is solid iron, and the outside is made of nylon material with added silver ions to play a role in sterilization and disinfection.

SDH Hardware, as one of the most professional architectural hardware manufacturers in China, has focused on European standard door hardware production for more than 10 years, providing door hinges, mortise lock, lcok cylinder and handle with competitive prices.

Contact us:

Contact: Mag Liu

Tel: 86-18364685393

Email: mag@euprotek.com