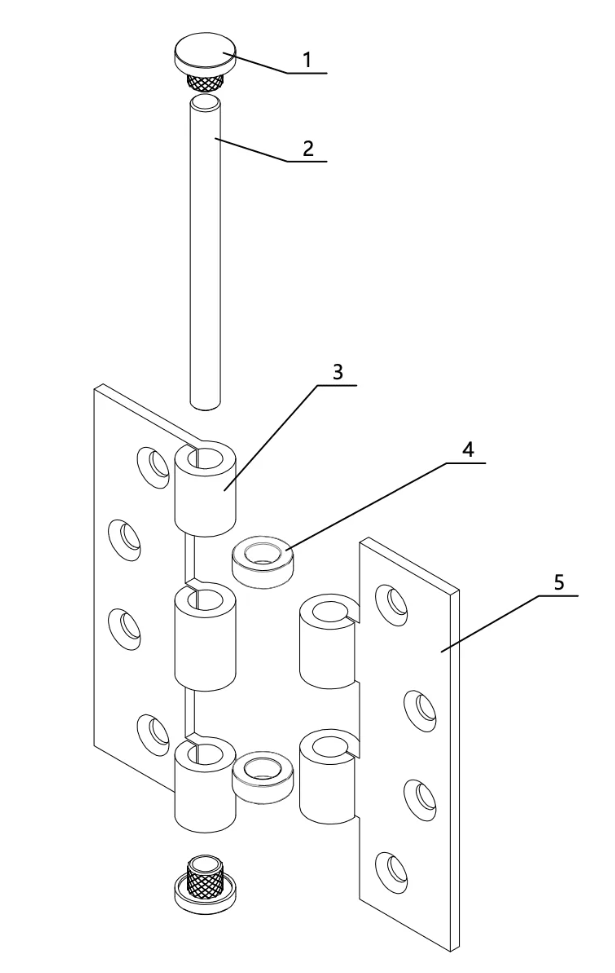

Hinge is a metal fitting that connects two objects and allows them to rotate around an pin. It is widely used in openable and closable structures such as doors and windows, cabinet doors, and furniture. The basic structure generally includes a pin, a rod, hinge leaves, and ball bearings.

Classification of Hinges

Classification by Material

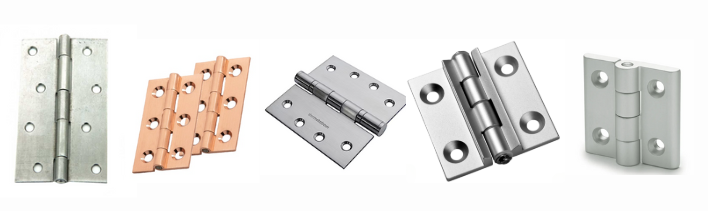

Generally divided into iron hinges (electroplating and painting on the surface), copper hinges, and stainless steel hinges. Other materials for making hinges include aluminum and zinc alloy.

- Iron hinges. Iron hinges are strong and low cost, but they are easy to rust and not beautiful enough.

- Copper hinges. Nice appearance but with high material cost.

- Stainless steel hinges. High strength, high material cost, corrosion-resistant. It is the mainstream material for making butt hinges.

- Aluminum hinges. Rich colors. But generally only used on aluminum alloy doors.

- Zinc alloy hinges. Nice appearance, low cost. Not strong enough, generally low copper content.

Classification by Function

According to the different functions and installation methods, they can be roughly divided into two categories: ordinary hinges and detachable hinges.

- Ordinary hinge. It does not distinguish between up and down directions during installation. It is quite common in the market.

- Security hinge. Non-Removable Pin Hinges, Continuous Hinges(Piano Hinges), Security Tab or Stud Hinges.

- Detachable Hinges (also known as Quick-Release Hinges or Self-Detaching Hinges) are hardware connectors designed with specific mechanical structures to enable rapid installation and removal of cabinet doors from frames without tools. The tapered end of the hinge’s axial core is embedded with a ball bearing to achieve point contact, thereby reducing friction. This design facilitates effortless door detachment, making such hinges widely adopted in the Russian market. Subtypes of Detachable Hinges Include: A. Curved-Leaf Hinge. Features a bend with a specific curvature on the hinge leaf. B. Lift-off Hinge. Utilizes door weight to enable automatic closing, functioning as a simplified door closer. C. Welded Hinge. Exclusively used for metal doors, where the hinge is welded directly onto the door surface. Typically made of iron, these hinges may include bearings or operate without them.

Other Classification

- According to the shape: square ends and round ends

- According to the shape of the decorative head, they are divided into: semi-dome flat head hinges, trumpet head hinges, pagoda head hinges, flat tower head hinges. The decorative head is divided into copper, zinc alloy, and iron according to the material.

- Other styles of hinges. A: Flag hinges. B. Drill-in hinges, mostly used on doors in Germany and Italy. C: “H” hinges, mostly seen in the Spanish market. D: Spring hinges. E: Concealed hinges, available in zinc alloy and stainless steel. External hinges (hollow hinges).

Hinge Structure

Hinge Production

The hinge manufacturing methods can be divided into two categories:

Made with profiles: copper hinges, aluminum hinges, and zinc alloy hinges. The hinges are formed by extrusion.

Made by stamping: stainless steel and iron hinges. The dog ears are made by stamping.

Load Bearing and Life of Hinges

- Deformation test requirements

- The upper and lower ends of the hinge are designed with an open gap, and the allowable deformation under pressure test is graded as follows:

- Qualified level: deformation ≤ 0.5mm (2 hinges)

- Strengthened level: 0.5mm<deformation<1mm (3 hinges)

- Unqualified: deformation ≥ 1mm

- The upper and lower ends of the hinge are designed with an open gap, and the allowable deformation under pressure test is graded as follows:

- Load-bearing configuration standard

- When the door weight is >50kg, it is recommended to use 3 hinges for installation

- Durability

- Standard hinge: ≥200,000 cycle tests

- Flush hinge: ≥100,000 cycle tests

Common Quality Issues about Hinges

- The two hinge leaves cannot be completely closed. Reason: The shaping is not in place after blanking.

- The hinge shell is broken. Reason: The material does not meet the standard.

- The surface is pitted and pitted. Reason: The raw material is not polished in place.

- Large area of yellow. Reason: Uneven electroplating.

Conclusion

This blog introduce the classification, structure, durability test, and common problems of hinges. If you have any questions, please contact us.

TEL:+ 136 0540 4113

Email: abby.lee@euprotek.com