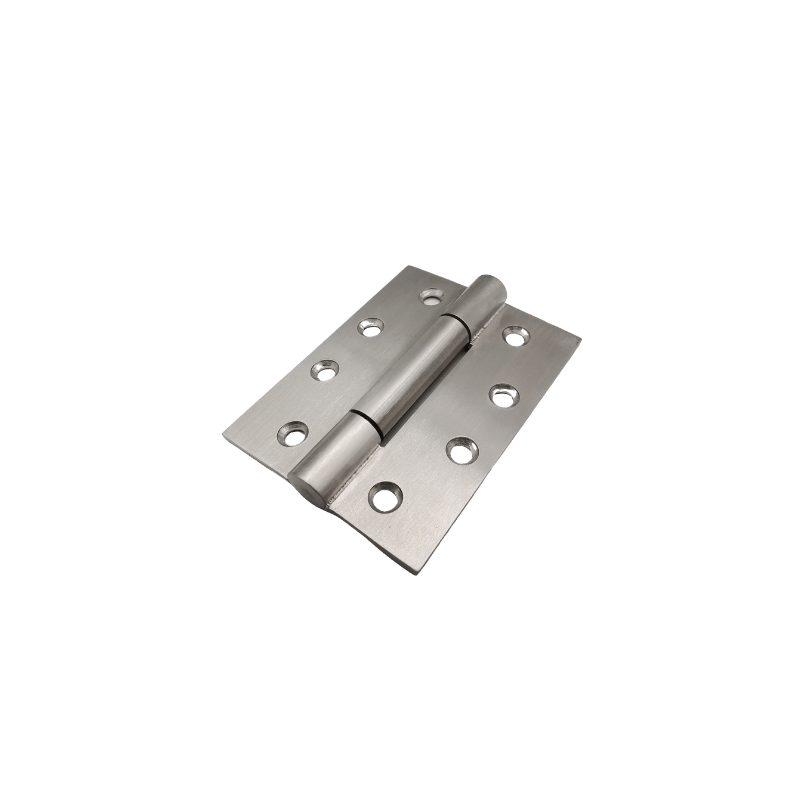

In industrial environments, constant mechanical stress, heavy loads, corrosive elements, and high-frequency operation can affect the performance of door hardware. Butt hinges play a key role in industrial applications with their high load-bearing and durable characteristics. This article explores the industrial-grade applications of butt hinges, their design adaptability for special scenarios, and installation best practices to meet the stringent requirements of global industries.

Challenges of Industrial Environments and the Role of Butt Hinges

Industrial environments, such as manufacturing plants, warehouses, and heavy machinery facilities, require hardware that goes beyond standard commercial use.

Key challenges include:

- Heavy Duty: Doors on industrial equipment, storage units, or explosion-proof enclosures often weigh hundreds of kilograms.

- Corrosive Environment: Exposure to chemicals, moisture, or salt air requires corrosion resistance.

- High Frequency Use: Doors in logistics centers or production lines may experience thousands of cycles per day.

- Safety Compliance: Hinges must prevent doors from sagging, misalignment, or sudden failure to protect people and assets.

The Role of Butt Hinges:

- Load Capacity: Reinforced joints and pivot pins distribute weight evenly.

- Material Innovation: Stainless steel, galvanized steel, or brass alloys resist rust and degradation.

- Custom Engineering: Adjustable tension, lubrication ports, and sealed bearings improve performance.

Industrial applications of butt hinges

1. Heavy machinery access doors

Large industrial machinery, such as turbines or CNC equipment, requires safe and easily accessible panels for maintenance.

- Use 4–6 mm steel plates to prevent deformation.

- Use greased pins: Reduce friction and wear in high-cycle operations.

- Use tamper-proof screws: Ensure safety.

2. Industrial facility doors

From hangar doors to fireproof partitions, butt hinges ensure smooth operation under pressure.

- Fireproof hinges: Made with a refractory alloy, these hinges maintain integrity in emergency situations.

- Explosion-proof hinges: Designed specifically for chemical plants, they use non-ferrous materials to eliminate the risk of sparks.

Installation Tips

- Use a laser level to ensure hinges are coplanar to prevent jamming.

- Reinforcement: For doors weighing more than 300 kg, weld or bolt the hinge plate to the structural support.

- Lubrication: Apply high-temperature grease to the pivot point in high-friction environments.

Why choose SDH heavy-duty butt hinges?

- Cost Efficiency: Reduced replacement frequency reduces long-term expenses.

- Safety Assurance: Meets BS EN 1935 grade 14 standards.

- Global Adaptability: Tailor-made solutions for different climates, from arctic cold storage to desert mining operations.

Conclusion

Using butt hinges in industrial environments requires careful consideration and selection of heavy-duty butt hinges with good load-bearing capacity. This will ensure safe industrial production processes. This article introduces the application of butt hinges for industrial use. If you have further questions, please contact us.