Cleanroom doors are critical components in controlled environments such as hospitals, laboratories, pharmaceutical plants, and food-processing facilities. They are designed to maintain air tightness, prevent contamination, and withstand frequent use. While panels, seals, and locks are often highlighted, the hinge is one of the most vital parts of cleanroom door hardware. A hinge not only determines how smoothly a door operates but also influences long-term durability, maintenance costs, and compliance with hygiene requirements.

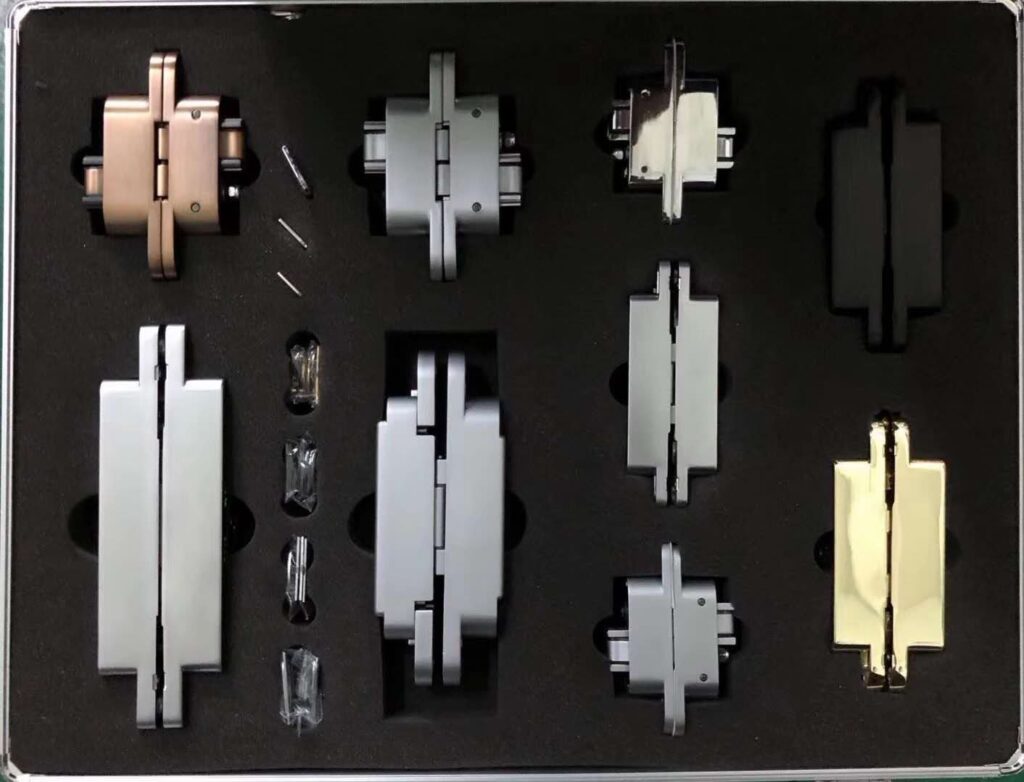

This article explores the different types of hinges commonly used in cleanroom doors, their applications, and highlights two advanced solutions from SDH Hardware—the oil-free butt hinge and the 3D adjustable concealed hinge.

Common Types of Hinges in Cleanroom Doors

1. Detachable Hinges

Detachable hinges(flag hinge) are designed for easy installation and removal of door panels. By allowing the door leaf to be lifted off without unscrewing the entire hinge, these are practical in cleanroom environments where maintenance or replacement may be frequent. They are commonly used for lighter cleanroom doors, such as those with steel or aluminum honeycomb cores.

Advantages:

- Easy door removal for cleaning or replacement

- Time-saving during maintenance

- Compact structure

2. Concealed Hinges

Concealed hinges are hidden within the door frame, offering a seamless and flush appearance. For cleanroom applications, this not only improves aesthetics but also minimizes dust accumulation and facilitates better sealing. Concealed hinges are suitable for high-end projects where cleanliness and design must work hand in hand.

Advantages:

- No visible hardware, ensuring a smooth door surface

- Improved hygiene due to fewer exposed edges

- Enhanced safety, reducing pinch points

3. Pivot Hinges (Floor Hinges or Pivot Sets)

Pivot hinges are often used for swing doors that require a wider opening angle, such as hospital corridor doors designed for trolley or stretcher passage. They are mounted at the top and bottom of the door and allow the door to swing up to 180°.

Advantages:

- Wide opening angle for smooth passage

- Suitable for heavy-duty traffic areas

- Strong load-bearing capability

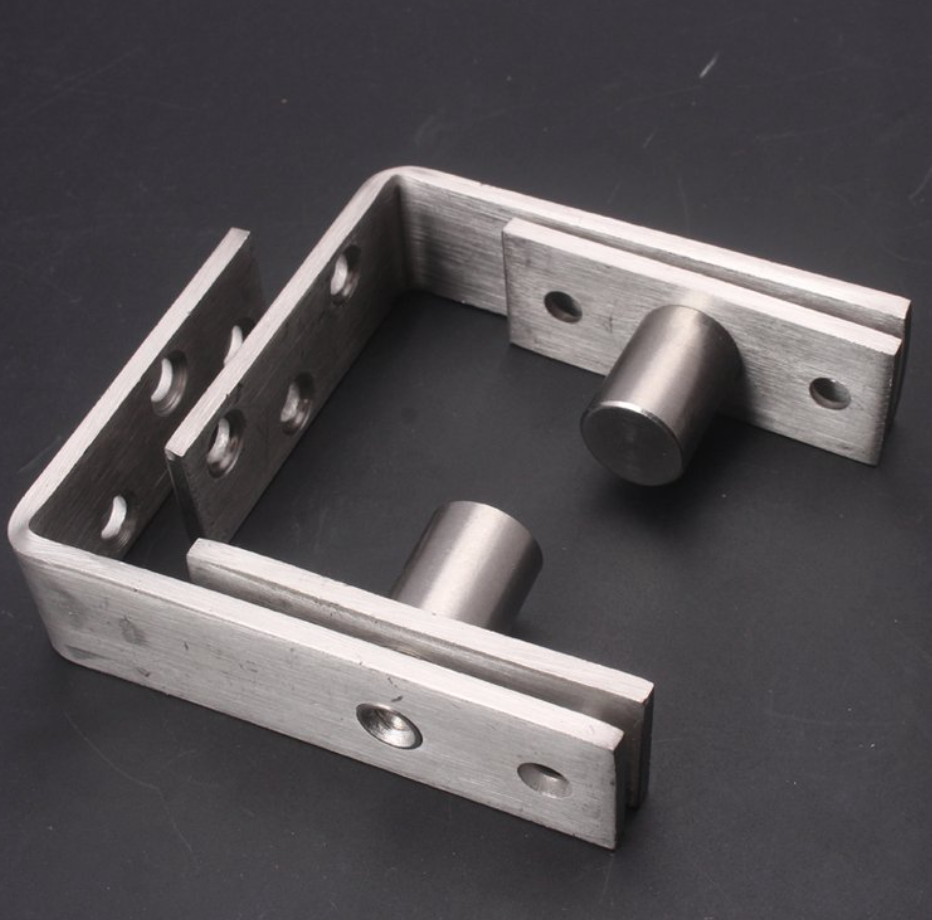

4. Stainless Steel or Aluminum Hinges

Standard stainless steel or aluminum butt hinges are durable, corrosion-resistant, and cost-effective. They are widely used in cleanroom doors because of their strength and ability to resist chemicals or moisture.

Advantages:

- High durability and strength

- Excellent corrosion resistance

- Cost-effective solution for general cleanroom doors

Why Advanced Hinges Are Needed in Cleanroom Doors

While the above hinge types are suitable for different scenarios, advanced cleanroom facilities demand higher performance. Key requirements include:

- Low Maintenance: Hinges that do not require regular lubrication or adjustments

- Silent Operation: Essential for hospitals, labs, and pharmaceutical plants where noise must be minimized

- Durability: Capable of withstanding frequent cycles without loosening or wearing out

- Hygienic Design: No exposed grease, no gaps that trap dust, and corrosion-resistant finishes

To meet these needs, SDH Hardware offers two innovative solutions: the oil-free butt hinge and the 3D adjustable concealed hinge.

Oil-Free Butt Hinges – The Silent, Maintenance-Free Solution

The oil-free butt hinge is specifically engineered for cleanroom and high-standard architectural projects. Unlike traditional hinges that rely on lubricating oil for smooth movement, oil-free hinges are designed with advanced internal mechanisms that eliminate the need for grease.

Key Advantages

- Maintenance-Free Performance

- No lubrication is required, preventing oil leakage or contamination.

- Reduces maintenance costs and downtime.

- Silent Operation

- Built to operate smoothly without squeaks or resistance.

- Ideal for hospitals, laboratories, and pharmaceutical environments where silence is critical.

- Durability & Load Capacity

- Heavy-duty stainless steel structure ensures strength.

- Tested to withstand 200,000+ cycle test.

- Load-bearing capacity up to 160 kg, suitable for heavy cleanroom doors.

- Corrosion Resistance

- Designed to perform in humid, chemical, or high-temperature environments.

- Prevents rust and ensures long-term stability.

Applications

- Hospital cleanroom doors

- Pharmaceutical plant doors

- Food processing workshop doors

- Laboratory containment rooms

By eliminating oil, the hinge avoids one of the most common contamination risks in controlled environments—oil leakage that can compromise sterility. This makes the oil-free butt hinge one of the best solutions for modern cleanroom facilities.

3D Adjustable Concealed Hinges – Flexibility Meets Aesthetics

Another advanced solution for cleanroom door systems is the 3D adjustable concealed hinge. These hinges are fully hidden inside the frame and door leaf, creating a flush, seamless appearance while offering exceptional adjustability.

Key Advantages

- Invisible Design

- The hinge is completely hidden when the door is closed.

- Ensures a smooth, clean surface that minimizes dust accumulation and supports hygienic cleaning.

- 3D Adjustability

- Allows fine-tuning in height, depth, and width.

- Makes installation more precise and ensures perfect door alignment, even after long-term use.

- Load-Bearing Flexibility

- Available in multiple load capacities, from 15 kg to 300 kg, meeting different project requirements.

- Suitable for lightweight interior doors as well as heavy-duty cleanroom doors.

- Durable Performance

- Zinc alloy and stainless steel options for strength and longevity.

- Tested to 200,000+ cycles, ensuring reliable performance in high-frequency usage environments.

Applications

- High-end cleanroom doors

- Modern laboratory interiors

- Hidden doors in pharmaceutical or medical facilities

- Minimalist architectural projects

With their adjustability and sleek design, 3D concealed hinges are not only functional but also enhance the overall appearance of cleanroom doors.

Why Choose SDH Hardware Hinges

At SDH Hardware, we specialize in professional hinge solutions for cleanroom, architectural, and industrial applications. Our hinges are engineered with strict attention to durability, hygiene, and ease of installation.

- Compliance with Standards: Products manufactured to meet EN1935 standard

- OEM & ODM Services: Tailor-made solutions available for different project needs, including custom finishes, sizes, and performance levels.

- Proven Reliability: Hinges tested through rigorous cycle testing (up to 200,000 cycles) for guaranteed longevity.

- Material Excellence: Options in zinc alloy, stainless steel (SS304, SS316), and other premium materials.

Conclusion

Cleanroom door hardware requires hinges that are not only strong and durable but also silent, hygienic, and easy to maintain. While traditional hinge types like detachable, concealed, pivot, and stainless steel hinges remain widely used, advanced solutions offer greater reliability for demanding projects.

The oil-free butt hinge ensures maintenance-free, silent, and contamination-free operation, making it ideal for cleanroom environments. The 3D adjustable concealed hinge delivers flexibility and aesthetic appeal while meeting heavy-duty performance needs.

By choosing SDH Hardware’s hinge solutions, architects, contractors, and project managers can ensure that cleanroom doors meet the highest standards of safety, performance, and hygiene.

👉 For more details, technical specifications, and OEM/ODM inquiries, please contact us at info@sdhhardware.com.