When we were decorating, people paid a lot of attention to the material and type of the door, but few people noticed that the various functions provided by the door were completed basis on hinges, and the work of the door is inseparable from the fit of the hinges.

A hinge is an important tool for connecting the door frame and the door leaf. It plays the role of bearing load and allowing the door to open and close smoothly. Every time the door is opened and closed at home, the hinge is required, and the frequency of use is extremely high. If the quality of the hinge is not good, The door panel will sink, the inferior hinges will make annoying noises during use, and some even have potential safety hazards.

So, what are the types of hinges?

Flush hinge

The structure of this hinge is quite special. It is composed of two pieces, the inner and outer pieces, just like the mother and child. The two pieces are in the same plane when closed, so there is no need to make grooves on the door and door frame, it is easy to install. There are holes in the daughter and mother pieces, and the door leaf and the door frame can be opened and closed by installing screws.

The advantage of this kind of hinge is that it does not need to be slotted, but the disadvantage is that the load-bearing capacity of the mother-child hinge is not good enough. From the perspective of durability, it is not as durable as a butt hinge.

Butt hinge

This is a very common hinge. Its structure is very simple, consisting of two steel plates with a thickness of 3mm and 2 or 4 bearings (depending on the model), According to BS EN 1935, which can withstand 200,000 opening and closing times. The side of the sheet with three fixed shafts needs to be installed on the door frame, and the side with two fixed shafts is installed on the door leaf. Common flat hinge materials are 201 stainless steel and 304 stainless steel, the latter has better corrosion resistance and is suitable for construction in coastal cities

The butt hinge has a strong load-bearing capacity and is more durable than the flush hinge, but because the surface of the butt hinge will have exposed parts after it is installed, it is less aesthetically pleasing to use.

Anti-theft hinge

Compared with ordinary hinges, the anti-theft hinge has one-to-one corresponding safety buckle nails and buckle nail holes on the two sheets. When the door leaf is in the closed state, the safety buckle nails will be buckled into the safety buckle nail holes. , which can prevent the door leaf from being disassembled after the hinge is damaged, thus playing a role in safety.

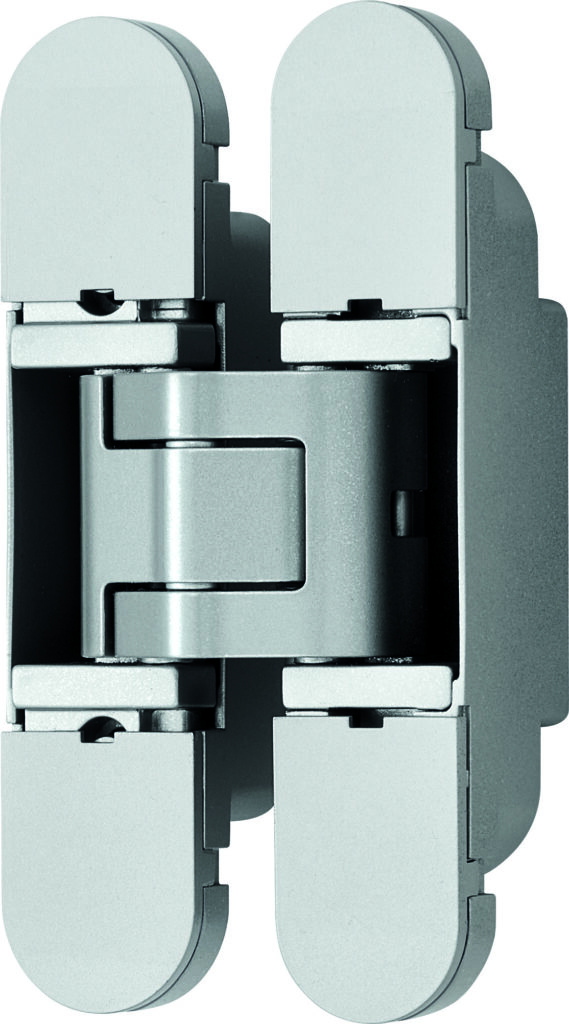

Three-dimensional adjustable hinge

The 3D adjustable hinge is a hinge with multi-directional adjustment, which is very useful. The error of slotting when installing the hinge and the sagging of the back door after long-term use can be adjusted directly without reinstalling new hinges.

So the application of 3D adjustable hinges is very extensive, and we can find it on various doors and cabinet doors.

The hidden design can make the combination of the door leaf and the door frame more perfect. It is installed on the side of the door leaf and the door frame without any exposed parts, which is very beautiful. If there is a problem with the cooperation between the door leaf and the door frame, there is no need to remove the door leaf. With a hexagon wrench, the door can be adjusted to the door gap in three directions of the door frame, and repeated installation will not cause damage to the door.

The three-dimensional adjustable hinge has a longer service life, does not rust or fade, and does not have to worry about oil leakage after using it for a long time. In contrast, it is more hygienic and durable.

Our recommendations:

CH60 3D concealed hinge

Suit for wooden doors

Suit for flush doors

Materials: Zinc alloy

L/W/Gap: 120/24.8/14.3mm

With 3D adjustable vertical±2mm, horizontal-2mm, +3mm, and depth±1mm

Max door weight with 2 hinges: 40kg

Door thickness: 29-45mm

Reading the material of hinges:

Common metal materials for manufacturing hinges are as follows:

- 201 Stainless steel: Chromium content is 16%-18%, the nickel content is 0.3%-1.2%, with certain acid and alkali resistance, high density, high hardness, no bubbles, and no pinholes.

- 304 Stainless steel: Chromium content is 18%-20%, the nickel content is 8%-11%, It has good corrosion resistance, heat resistance, low-temperature strength, and mechanical properties; good hot workability such as stamping and bending, and no heat treatment hardening (use temperature -196 ° C ~ 800 ° C). Corrosion-resistant in the atmosphere.

- 316 Stainless steel: Chromium content is 16%-18.5%, the nickel content is 10%-14%, the molybdenum content is 2%-3%. Its corrosion resistance and high-temperature strength are greatly improved, and the high-temperature resistance can reach 1200-1300°.

- Zinc alloy: It has good casting performance and can die-cast precision parts with complex shapes and thin walls, and the surface of the castings is smooth. Surface treatment is possible: electroplating, spraying, painting, polishing, grinding, etc.