The 3D adjustable concealed hinge is a popular architectural hardware. It is characterized by being adjustable after installation and completely hidden. It is widely used in high-end decoration and is deeply loved by users.

Types

According to whether it can be adjusted, it can be divided into non-adjustable concealed hinge (also known as SOSS hinge), 2-D adjustable hinge, 3-D adjustable hinge

According to the material of the hinge, it can be divided into zinc alloy hinge, aluminum alloy + zinc alloy hinge, stainless steel hinge

Special version: self-closing hinge

Advantages

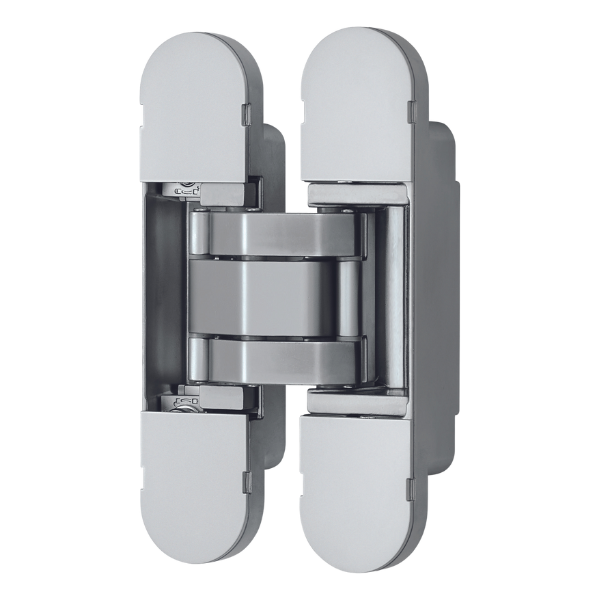

- Beautiful: The hinges are completely hidden after installation, suitable for doors on TV walls/art walls. The hinge is made of zinc alloy/stainless steel, and is painted by electroplating process, with beautiful appearance.

- The 3D adjustable hinge can ensure that the door leaf is in the most perfect position with the door frame during installation. After a long period of use, if the door leaf sags and touches the ground, the door leaf can also be adjusted to return to the normal position.

Usage scenarios and how to choose

Applicable scene

3D adjustable concealed hinge is suitable to the doors on walls that need to remain intact. The fire protection time of hinges made of zinc alloy or aluminum alloy is 30/60 minutes, and the fire protection time of hinges made of stainless steel is as high as 2-4 hours, which is more suitable for steel fire doors.

How to choose

According to the weight of doors. The weight of the door should not exceed the load-bearing capacity of the hinges, and the nominal load-bearing capacity is the maximum load-bearing capacity for a group of 2 hinges. When the number of hinges is increased to 3 or more, the load-bearing capacity will be increased by 20-30 minutes, but we do not recommend using more than 5 hinges on a door, which will cause trouble for adjustment, door leaf and hinge Pages may be damaged due to uneven force.

According to the size of doors. It is recommended to install 3 hinges for doors with a height of 2.1 meters or less. It is recommended to install 4 hinges for doors with a height of 2.1m-3.8m.

The width of the hinge should be less than the thickness of the door and greater than half of the thickness of the door. There should be a gap of more than 3mm between the installed hinge and both sides of the door leaf.

If you are using a hollow core door with a solid wood frame, the hinges should not be thicker than the solid wood frame, and the slots should not penetrate the frame when installing the hinges. If you are using an aluminum profile frame door, the thickness of the hinge should not exceed the width of the aluminum profile due to the size limit of the aluminum profile cavity. And should use tooling to fix the hinge.

If you have high requirements for fire resistance, choose hinges made of stainless steel.

It is recommended to use round head hinges for wooden doors, and it is more convenient to slot during installation.

EU standard

- The current standard EN1935 is for single-axis hinges, and 3D hidden hinges are mostly 5-axis and 7-axis. There is no specific standard yet. So the current concealed hinges are temporarily tested and rated according to EN1935.

- The 3D hidden hinge provided by SDH hardware has a durability of 200,000 times.

How is the hinge produced

ZDK#3 zinc alloy is melted from a square billet and die-cast into hinge parts. Zinc alloy has good fluidity, and after applying pressure to the zinc alloy solution, it can cast parts with high precision. And the zinc alloy has certain corrosion resistance, which is the main material of the load-bearing hinge of 80 kg or less.

After casting, the parts will be ground for the next step of surface treatment, They will be dyed different colors according to customers’ requirements in the electroplating factory.

After the electroplating is completed, the hinge parts will be assembled manually, undergo quality inspection, and then be packaged.

What kind of 3D concealed hinge is good?

The appearance is sound, with no defects or protrusions on the surface or edges of the part. Only good die-casting abrasive tools and technology can produce perfect die-casting parts.

The electroplating layer is uniform, the color is accurate, and there are no impurities and scratches. The effect of electroplating determines the appearance of the hinge, and a good hinge should have a perfect surface treatment.

A good hinge should open and close smoothly without jamming. The opening and closing of the hinges may be loose or tight, which is okay, but if there is a jam when opening and closing, this is a malfunction.

main failure mode

The most common failure mode is rocker arm fracture.

There are generally two reasons for this situation. One is that the weight of the door exceeds the load-bearing capacity of the hinge.

Another reason is long-term uneven force, and the hinge rocker arm is broken when the force is too heavy.

Recomandation

CH60-3D Adjustable Concealed Hinge for Wooden door and aluminum profile door

A concealed medium duty hinge for unrebated, flush faced quality timber doors and aluminum doors. With removable cover plates to conceal the adjustment screws. Comes with a 5-year mechanical guarantee.

Suitable for doors of 36mm min. thickness

Total length 135mm

Depth 25.5mm

Easy installation and slot symmetry

Hinge fixing position

60kg Weight Load

5 Year Manufacturers Warranty

With 3D adjustment: vertical: ±2.5mm, horizontal: ±2mm, and depth: ±1mm

SDH is a manufacturer specialized in 3D concealed hinge, We can provide you with OEM/ODM services, please contact us for details: alfred@euprotek.com