The European standard lock body with dead bolt must be used with the lock cylinder, which is also one of the most important accessories for security. Only if it is inserted correctly, can the cam in the lock cylinder be turned, and the cam will drive the dead bolt and unlock.

In some scenes with very high security requirements, such as important rooms in commercial buildings, gates of courtyard houses, etc., users hope to use lock cylinders with higher safety factors and more difficult to crack. In response to this demand, the security lock cylinder came into being, which has a more complex structure and higher security than ordinary lock cylinders. Whether facing violent demolition or forged keys to open the lock, it can last longer than ordinary lock cylinders.

So how does the security lock cylinder work? How does it play a security role?

The following content will be revealed to you.

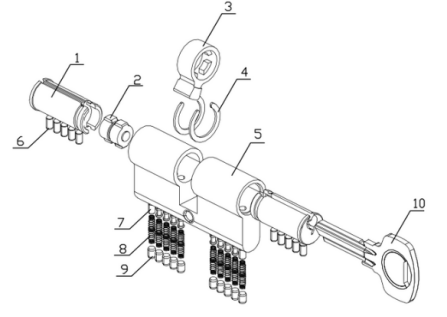

The following is a disassembly diagram of a common cylinder

- Cylinder core

- Clutch

- Cylinder cam

- Fix spring

- Cylinder body

- Cylinder core Pin

- Cylinder pin

- Spring

- Pin

- Key

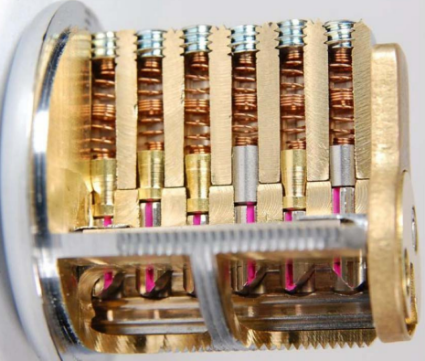

The main components in the pin-and-tumbler design are a series of small pins of varying length. The pins are divided up into pairs. Each pair rests in a shaft running through the central cylinder plug and into the housing around the plug. Springs at the top of the shafts keep the pin pairs in position in the plug. When no key is inserted, the bottom pin in each pair is completely inside the plug, while the upper pin is halfway in the plug and halfway in the housing. The position of these upper pins keeps the plug from turning — the pins bind the plug to the housing. Here’s how it works:

When you insert a key, the series of notches in the key push the pin pairs up to different levels. The incorrect key will push the pins so that most of the top pins are still partly in the plug and partly in the housing.

The correct key will push each pin pair up just enough so that the point where the two pins come together lines up perfectly with the space where the cylinder and the housing come together (this point is called the shear line). To put it another way, the key will push the pins up so that all of the upper pins are inserted completely in the housing, while all of the lower pins rest completely in the plug. Without any pins binding it to the housing, the plug moves freely, and you can push the bolt in and out.

Security lock cylinders are similar in structure to ordinary lock cylinders. The difference is as follows:

Ordinary lock cylinders only have 6 marbles in a single row, while security lock cylinders generally have more than two rows of marbles, and the number of keys that can be arranged and combined is greatly increased.

There is usually a serpentine groove on the key of the security lock cylinder, which corresponds to the paddle inside the lock cylinder, and the lock can only be unlocked if the position is correct.

The security lock cylinder is equipped with an anti-drill top, which is located in front of the pins of the lock cylinder. It is made of heat-treated high-hardness stainless steel, which is very difficult to be penetrated by tools such as electric drills.

SDH Hardware is a professional manufacturer of security lock cylinders, below are several recommended security lock cylinders produced by SDH.

This lock cylinder has double rows of pins and anti-theft nails.

This lock cylinder has double rows of pins, anti-theft spikes and serpentine grooves.

The security lock cylinder with higher security with a more ingenious structure, if you want to know more, please contact: alfred@euprotek.com