Commercial door handles are essential in providing durability, security, and aesthetic appeal in high-traffic environments such as offices, schools, hospitals, and hotels. The material selection is crucial in ensuring that the hardware can withstand frequent use and maintain its functionality over time. This blog will explore common materials used in commercial door handles, the benefits of each material, and the differences between commercial and residential door hardware.

1. Common Materials Used in Commercial Door Handles

Commercial door handles are crafted from various materials, each chosen based on its strength, appearance, and resistance to wear and corrosion. Here’s a look at some commonly used materials:

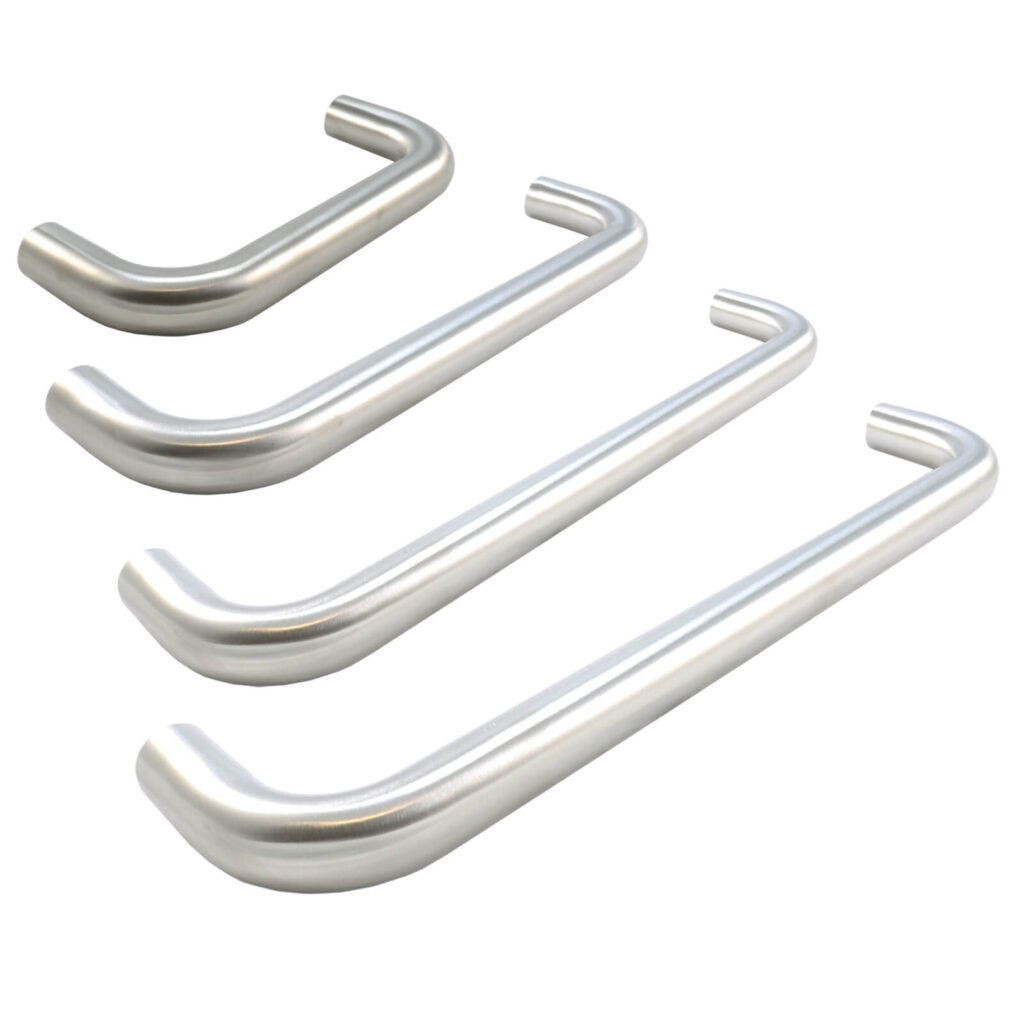

a. Stainless Steel

Stainless steel is one of the most popular materials for commercial door handles due to its durability, corrosion resistance, and sleek appearance. The high chromium content in stainless steel alloys forms a protective layer, which makes it resistant to rust and tarnishing. Stainless steel handles are especially suited for outdoor doors and locations exposed to moisture, because they can endure harsh environments while maintaining an attractive finish.

b. Brass

Brass is a traditional and reliable material for door handles, known for its antimicrobial properties. This feature makes it a favored choice in healthcare facilities, where hygiene is a top priority. Brass is also highly malleable, allowing manufacturers to create intricate designs suitable for more decorative door hardware. Additionally, its natural golden hue lends a timeless appeal, which is valuable in upscale commercial settings.

c. Aluminum

Aluminum is lightweight, durable, and highly resistant to corrosion, making it ideal for busy commercial spaces. Although not as strong as stainless steel, aluminum handles can be anodized to improve hardness and resistance to wear. This anodization process also allows aluminum to be colored, giving designers flexibility in matching or complementing interior decor. Aluminum handles are often used in office buildings and retail spaces due to their cost-effectiveness and versatile appearance.

d. Zinc Alloy

Zinc alloys, such as Zamak, are frequently used in commercial door handles because they are cost-effective and versatile. Zinc is known for its strength and corrosion resistance, and it is often plated with chrome or nickel to enhance its appearance and durability. Zinc alloy handles are generally more affordable than stainless steel or brass and can be molded into various shapes, making them suitable for both functional and decorative applications in commercial environments.

e. Bronze

Bronze, especially oil-rubbed bronze, is a popular material for its distinctive dark finish and traditional aesthetic. Like brass, bronze has natural antimicrobial properties, adding an extra layer of protection in environments where sanitation is important. It is often used in historic or traditional buildings because it develops a unique patina over time, enhancing its vintage appeal.

f. Plastic and Nylon

In certain commercial applications where cost savings and color flexibility are priorities, handles may be made from heavy-duty plastic or nylon. While not as durable as metal, these materials are impact-resistant and can be coated to enhance their scratch resistance. Plastic handles are more commonly used in less demanding areas or as parts of complex locking mechanisms rather than as the primary material for the handle itself.

2. Benefits of Different Materials

Each material offers unique benefits, making certain options more suitable for specific environments. Here’s a closer look at these advantages:

Stainless Steel:

- Durability: It withstands heavy usage without significant wear.

- Corrosion Resistance: Stainless steel is ideal for high-moisture areas.

- Aesthetic Appeal: Offers a modern look that fits most commercial interiors.

- Hygienic: Easy to clean, contributing to sanitation standards in healthcare.

Brass:

- Antimicrobial Properties: Naturally kills bacteria, suitable for healthcare settings.

- Elegant Appearance: Its warm, golden color adds a classic touch.

- Malleability: Allows for intricate designs, making it valuable in custom hardware.

Aluminum:

- Lightweight: Easier to install and handle.

- Corrosion Resistant: Anodized aluminum is particularly durable.

- Cost-Effective: Lower price point for large commercial projects.

- Customizable: Available in various colors and finishes.

Zinc Alloy:

- Strength and Affordability: Strong yet cost-effective, ideal for mass production.

- Versatile Finish Options: Can be chrome or nickel-plated for a premium look.

- Design Flexibility: Easily cast into unique shapes for different applications.

Bronze:

- Distinctive Appearance: Develops a patina, enhancing vintage or rustic looks.

- Antimicrobial Properties: Adds a layer of protection in public spaces.

- Durability: Withstands frequent use and resists corrosion.

Plastic and Nylon:

- Cost-Effective: Affordable option for low-traffic or non-demanding areas.

- Impact-Resistant: Suitable for handles or parts that may encounter impact.

- Color Options: Easily produced in a variety of colors to match décor.

3. What Is the Difference Between Commercial and Residential Door Hardware?

While both commercial and residential door hardware serve similar purposes, their requirements and features differ considerably due to the distinct environments in which they are used. Below are key differences between the two:

a. Durability and Strength

Commercial door hardware is designed to withstand heavy use, often exceeding 100,000 cycles, which is far more than typical residential hardware. Materials used in commercial handles are generally stronger, ensuring they can handle frequent usage without deterioration. This durability is essential for public buildings where handles experience constant daily use.

b. Security Standards

Security is a significant concern in commercial settings, where door hardware must comply with strict safety and fire regulations. For the purposes of European standardisation, EN 1906 has been introduced to specify requirements and test methods for door handles. The stardard guarantee that commercial hardware provides adequate protection against forced entry and can withstand fire conditions.

c. ADA Compliance

Commercial door hardware must often meet the Americans with Disabilities Act (ADA) requirements to ensure accessibility. This compliance dictates specific design features, such as lever-style handles that can be operated easily without requiring tight grasping, pinching, or twisting. This contrasts with residential hardware, which does not necessarily have to meet these standards unless required by local regulations.

d. Aesthetic Considerations

While aesthetics are important in both settings, residential hardware may prioritize unique or custom designs that match home decor. In contrast, commercial hardware often balances style with practicality, focusing on finishes that are easy to clean and maintain. The aesthetic choices in commercial settings usually lean toward durability and neutrality, with finishes like stainless steel, satin nickel, or anodized aluminum being popular due to their professional appearance.

e. Cost

Commercial door hardware generally comes at a higher cost due to its durability, compliance requirements, and often more complex locking mechanisms. Although the initial investment in commercial-grade materials is higher, it pays off in longevity and reduced maintenance, whereas residential hardware is typically more budget-friendly upfront but may require more frequent replacement.

Conclusion

The choice of material for commercial door handles significantly impacts durability, appearance, maintenance, and overall performance. Materials like stainless steel and brass offer both strength and aesthetic value, making them ideal for high-traffic, demanding environments. Zinc alloys and aluminum provide cost-effective options for large-scale projects, while bronze and specialized plastics offer unique qualities for particular applications. By understanding the material properties and design standards, facility managers and designers can select door hardware that meets both functional and regulatory requirements, ensuring safety, durability, and aesthetics in commercial settings.

When selecting door hardware, it’s essential to consider not only the immediate cost but also the longevity, security, and maintenance needs to make a well-rounded investment that will withstand daily use in a commercial environment.